What Is Residual Capacity? (And Why It Matters When Lifting High Loads)

Understanding the true lifting capability of a forklift is essential for warehouse operators, logistics teams, construction sites and any business handling heavy materials. While most people focus on a machine’s rated lifting capacity, the more important figure in day-to-day operations is residual capacity. This determines how safely your forklift can handle loads, especially when lifting to higher heights or using attachments.

Below, we break down what residual capacity means, the factors that influence it, and how it affects safety and performance when working with high or awkward loads.

What Is Residual Capacity?

Residual capacity is the actual lifting capacity of a forklift once real-world operating conditions are considered. Although every forklift comes with a manufacturer’s rated capacity (for example, 2,500 kg), that figure only applies under ideal conditions such as a standard load centre and no added attachments.

In practical environments, the forklift’s true usable capacity decreases. This reduced figure is the residual capacity. It reflects how much weight the forklift can safely lift at a given height with a specific load type, mast configuration, and attachment setup.

Rated Capacity vs Residual Capacity

While the rated capacity represents the forklift’s maximum theoretical lift, the residual capacity is what operators can actually rely on. Several factors reduce the capacity from the brochure number, such as:

- Forklift load centre shifts

- Forklift mast height

- Tilt angles

- Additional forklift attachments

- Load shape and stability

- Tyre type and condition

- Forklift age and overall condition

Understanding this difference helps prevent overloading, tipping risks and damage to your machinery.

Why Residual Capacity Matters When Lifting High Loads

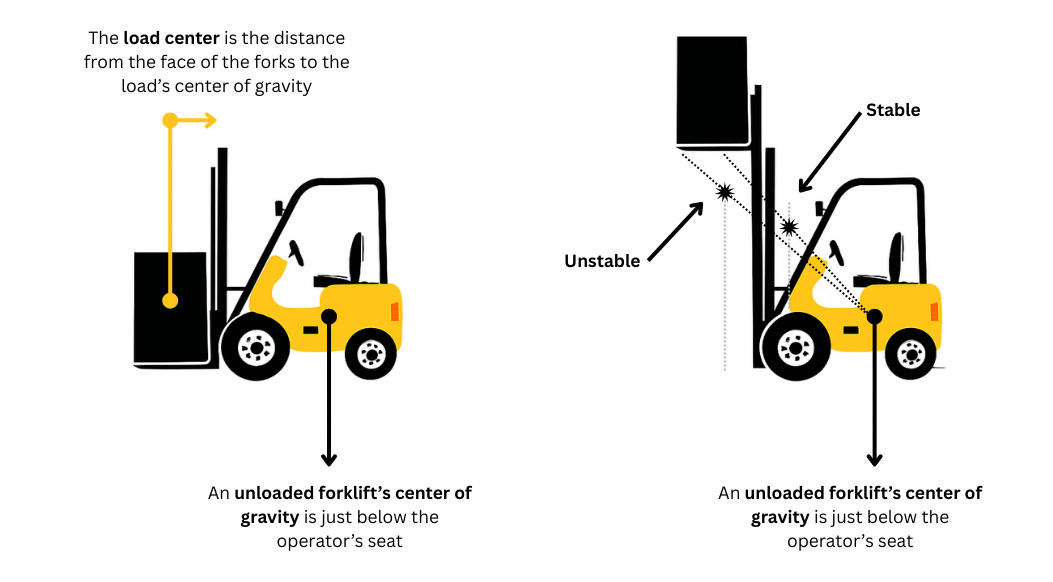

As lifting height increases, the forklift’s centre of gravity shifts. This shift reduces stability, meaning the forklift cannot lift the same weight at 4 metres as it can at ground level. Without considering residual capacity, operators may unknowingly exceed safe limits.

Key reasons it matters:

- Safety – Prevents overturning accidents caused by an unstable centre of gravity

- Efficiency – Ensures the correct forklift is selected for each job

- Compliance – Reduces workplace health and safety risks

- Equipment longevity – Prevents damage to masts, hydraulics and tyres

- Load protection – Avoids the risk of dropping or damaging goods at height

How Load Centre Affects Residual Capacity

The load centre is the distance from the vertical face of the forks to the load’s centre of gravity. Standard forklifts are rated at a 500 mm load centre. If the load is longer, wider or awkwardly shaped, the centre of gravity moves forward, reducing the residual capacity.

Example:

A 2,500 kg forklift may only be able to safely lift 1,800 kg if the load centre increases to 600 mm. This reduction is normal and expected, which is why operators must always refer to the forklift’s capacity data plate.

How Attachments Reduce Residual Capacity

Attachments such as clamps, rotators, fork positioners, jibs and carpet poles add extra weight to the front of the forklift. This extra weight acts like extending the load centre, reducing stability and lowering residual capacity.

Even a lightweight attachment can significantly change the forklift’s balance point. Always ensure your forklift’s data plate has been updated to reflect any attachment fitted.

How to Calculate or Check Residual Capacity

Residual capacity is not something operators should guess. To determine the correct figure:

- Check the forklift’s data plate (capacity chart)

- Confirm the load centre based on the actual load

- Identify mast height and configuration

- Factor in any attachments

- Review the lift height for the task

- Ask your forklift supplier for a certified capacity calculation if uncertain

At Heavy Lift Forklifts, we can assist with accurate capacity ratings and help match the right forklift to your lifting requirements. We have a wide range of forklifts for hire (Melbourne), as well as official distributor for Bobcat and Hangcha.

Choosing the Right Forklift for High Lifts

If your operations involve stacking pallets in racking, loading trucks at height or handling long materials, selecting the correct forklift model is essential. Popular options include:

- High-mast counterbalance forklifts

- Reach trucks for narrow aisles

- Telehandlers for long or elevated loads

- Electric forklifts with high stability and precision

Our team can help you find the safest and most efficient model for your application. We offer a wide range of forklifts for hire, as well as new and used forklifts for sale, with delivery available across Melbourne and Victoria.

Common Mistakes Operators Make With Residual Capacity

- Assuming the forklift can lift its rated capacity at any height

- Ignoring the impact of attachments

- Using long or awkward loads without recalculating capacity

- Not checking the data plate

- Overestimating the forklift’s stability

- Failing to consider mast tilt or uneven surfaces

Avoiding these mistakes can prevent accidents and extend the life of your equipment.

Get Expert Forklift Advice

Our team can help you choose the safest and most efficient model for your needs. Explore our range of forklift hire Melbourne options or browse our forklifts for sale Melbourne, with fast delivery available across Victoria.