Load Centre vs Load Weight: Why 1,500kg Becomes Unsafe at 800mm

Forklift capacity is often reduced to a single number on the data plate. If the load weighs less than that figure, it is commonly assumed to be safe to lift and transport. In practice, that capacity only applies under specific conditions. Once those conditions change, the forklift’s safe working capacity can drop significantly.

A common and dangerous misunderstanding is treating load weight and load centre as the same thing. A 1,500kg load can become unsafe simply because its weight sits further forward on the forks. This misunderstanding contributes to tip overs, unstable steering, dropped loads, and near misses. The forklift may still lift the load, creating false confidence, even though it is operating outside safe stability limits.

What Load Weight Actually Means

Rated load weight is the maximum load a forklift can handle safely under defined conditions. It assumes a specific load shape, size, and position, operation on level ground, and no attachments fitted.

Manufacturers establish this rating during testing by balancing the counterweight, wheelbase, mast, and hydraulics against a standard load centre, usually 500mm or 600mm from the fork face. Under those controlled conditions, the forklift meets stability requirements and the result becomes the rated capacity.

This rating only applies while those conditions remain unchanged. Any increase in load centre, change in load shape, added attachment, raised lift height, or uneven surface immediately reduces the forklift’s safe capacity, even if the load weight itself stays the same.

What Load Centre Means in Real Terms

Load centre is the horizontal distance from the fork face to the centre of gravity of the load. As that distance increases, the load applies more leverage to the forklift, reducing stability.

In real operations, loads rarely match the standard assumptions used for rating. Deeper pallets, overhanging loads, stillages, IBCs, and irregular items push the centre of gravity forward.

Attachments such as fork extensions or clamps increase this distance further, often without operators realising how much stability is being lost.

As load centre increases, residual capacity decreases. A load that is within the rated weight can still exceed the forklift’s true safe capacity simply because its centre of gravity is further forward.

What a “1,500kg at 500mm” Rating Really Means

A rating of “1,500kg at 500mm” means the forklift can safely lift that load only if the centre of gravity sits exactly 500mm from the fork face. The load must be evenly distributed, positioned against the backrest, handled without attachments, and lifted on level ground.

Few real world loads meet these conditions. Many pallets are deeper than standard, loads are uneven, and attachments push the load forward. Even small changes in pallet depth or load shape can move the centre of gravity beyond 500mm or 600mm. When that happens, the original rating no longer applies and the safe working capacity is lower than the figure on the data plate.

How a 1,500kg Load Becomes Unsafe at 800mm

A forklift remains stable only while the load’s centre of gravity stays within its design limits. When a 1,500kg load shifts out to an 800mm load centre, the balance of the forklift changes significantly.

As the load moves forward, it creates greater leverage around the front axle. This increases the forward tipping force, even though the load weight has not changed. At 800mm, the load places far more stress on the forklift’s stability system than it does at 500mm.

In practical terms, a forklift rated at

1,500kg at 500mm may have a safe working capacity closer to

1,100kg or less at an 800mm load centre. The forklift may still lift the load, but steering, braking, and stability margins are reduced. The risk increases sharply when turning, braking, travelling on ramps, or lifting to height.

Why Forklifts Still Lift Loads That Exceed Safe Capacity

Forklifts can lift loads beyond their safe capacity because hydraulic power and stability are separate limits. The hydraulic system may have enough force to raise the load even when the forklift is already outside its stability envelope.

Stability depends on balance, not lifting force. Once the combined centre of gravity moves too far forward, the forklift operates with minimal margin. Steering becomes lighter, braking effectiveness drops, and resistance to tipping is reduced, especially during movement.

This leads to false confidence. If a similar load was lifted previously without incident, unsafe behaviour can become normalised. Eventually, a small change such as a sharper turn, higher lift height, or sudden stop is enough to cause a tip over or dropped load.

Load Charts and Data Plates

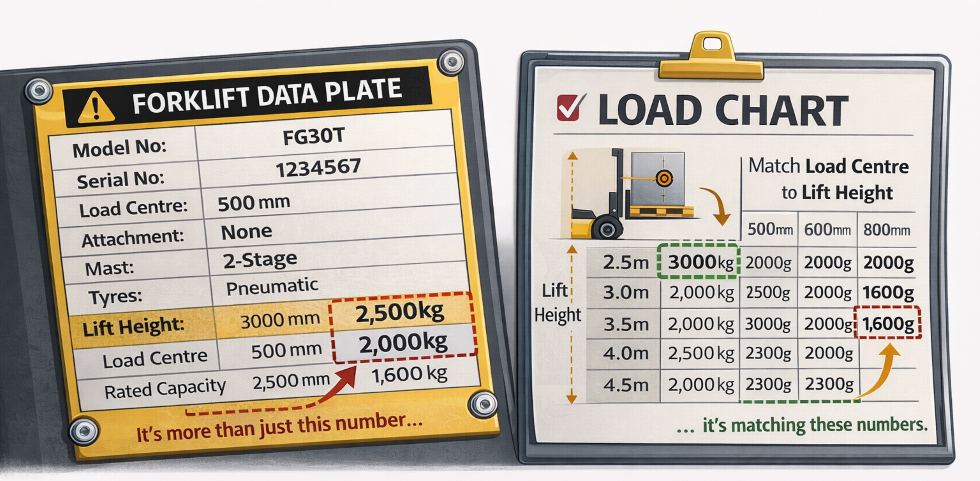

Data plates and load charts show the safe operating limits of a forklift, but they are often misread. The data plate lists capacity at a specific load centre and lift height, assuming standard conditions and no attachments.

Load charts show how capacity reduces as load centre increases, lift height changes, or attachments are fitted. To read a chart correctly, identify your load centre, then match it to the intended lift height. The figure at that point is the maximum safe capacity for that situation.

Common mistakes include focusing only on the highest capacity figure, ignoring reduced capacities at longer load centres, and failing to account for attachments. Load charts should always be read with an understanding of residual capacity, as they reflect how real operating conditions reduce stability.

Signs Your Load Centre Is Creating a Safety Risk

Early warning signs often appear before an incident.

- Light or vague steering indicates reduced rear axle traction.

- Reduced braking effectiveness increases stopping distances.

- Excessive mast tilt to feel stable suggests the load centre is already too far forward.

- Rear wheels lifting or feeling light is a clear sign the forklift is operating outside safe limits.

- Instability during normal movements such as turning, stopping, or crossing minor floor irregularities should never be ignored.

How to Reduce Risk When Load Centre Increases

When load centre increases, the safest response is to adjust the task, not push the forklift harder.

- Using a forklift suited to the pallet depth and load shape reduces reliance on narrow stability margins. Deeper or longer loads often require higher residual capacity or a longer wheelbase.

- Reducing lift height and travel speed lowers the combined centre of gravity and reduces dynamic forces. Keeping loads tight against the backrest minimises unnecessary forward shift.

- Attachments must be correctly rated and their impact on capacity understood before lifting. Most importantly, tasks should be reassessed if a load feels unstable. Breaking the load down or using different equipment is safer than continuing at the limit.

---

If limitations are affecting safety or productivity, the right forklift setup is critical. Heavy Lift Forklifts offers forklifts for hire in Melbourne, along with new and used forklifts for sale to suit different load shapes, pallet depths, and operating environments.

Whether you need short term hire for oversized loads or are reviewing your fleet to improve stability and residual capacity, our team can help you select equipment matched to the task. Speak with Heavy Lift Forklifts to discuss forklift rental or available forklifts across Melbourne.