Forklift Stability Triangle & Turning, Braking and Uneven Loads (Real Scenarios)

Most forklift operators have seen the stability triangle during training. It is usually shown as a simple diagram with three points and a shaded area in the middle. Easy enough to understand in theory, easy to forget once the warehouse gets busy.

But the forklift stability triangle is not just a classroom concept. It explains why forklifts tip during sharp turns, why sudden braking can be dangerous with a heavy load, and why uneven pallets create more risk than many people realise. Nearly every stability-related incident can be traced back to one thing: the combined centre of gravity moving outside that triangle.

In real warehouse conditions, forklifts are constantly accelerating, stopping, turning and lifting. Loads are not always perfectly balanced and floors are not always perfectly flat. When you understand how the stability triangle behaves in these everyday situations, you start to recognise risk before it becomes an accident.

What Is the Forklift Stability Triangle?

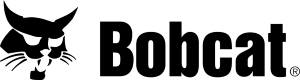

The forklift stability triangle explains how a forklift stays upright.

Most standard counterbalance forklifts sit on three support points: the two front wheels and the pivot point of the rear axle. If you connect those three points, you create a triangle. That triangle forms the machine’s stability base.

As long as the combined centre of gravity of the forklift and its load remains inside that triangle, the forklift stays stable. Once that balance point moves outside the triangle, the forklift tips forward or sideways.

Both the forklift and the load have their own centre of gravity. When a pallet is lifted, those two combine into one balance point. That combined centre of gravity shifts depending on load weight, load height, steering input, braking and surface conditions.

The stability triangle is not just about speed. It is about where that balance point sits at any given moment. Understanding that movement is what prevents tip-overs.

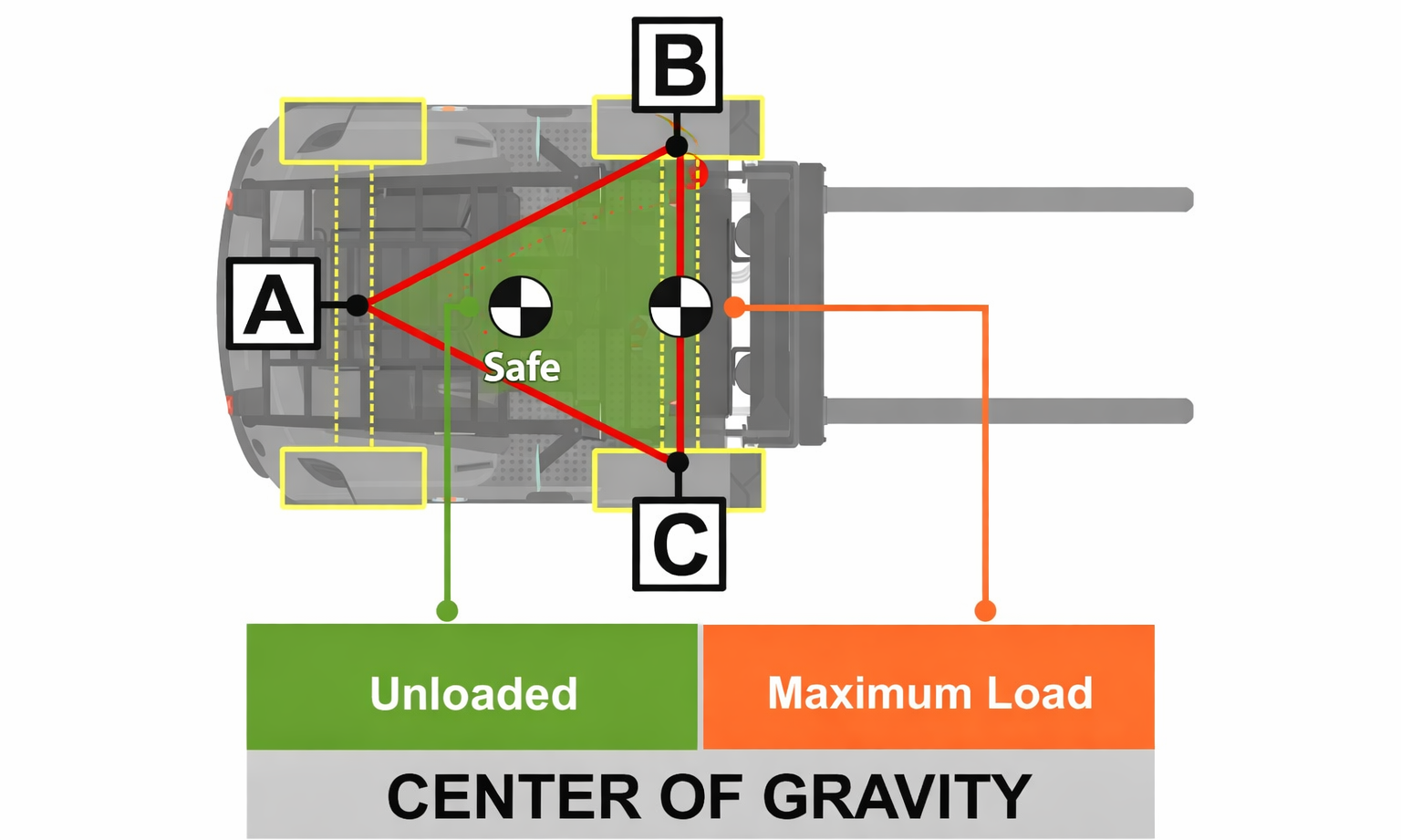

Scenario 1: Turning Too Fast with a Raised Load

This is one of the most common causes of forklift tip-overs.

Imagine an operator retrieves a pallet from the top beam and begins travelling without fully lowering it. At the end of the aisle, they take a corner a little too quickly.

Two things happen.

First, the raised load lifts the combined centre of gravity higher, which reduces stability. A higher centre of gravity makes the forklift more sensitive to sideways movement.

Second, when the forklift turns, centrifugal force pushes that centre of gravity outward toward the outside front wheel. The faster the turn, the stronger the force.

If the centre of gravity crosses the edge of the stability triangle, the forklift tips sideways. There is often little warning before it happens.

This is why most sideways tip-overs occur during turns. Keeping loads low and slowing before corners dramatically reduces this risk.

Scenario 2: Braking Hard with a Heavy Load

Braking may not feel as risky as turning, but it can be just as dangerous.

Picture an operator travelling with a heavy pallet. A pedestrian steps out unexpectedly, and the operator brakes suddenly.

When braking hard, weight shifts forward. The load continues moving due to momentum, pushing the combined centre of gravity toward the front axle. If that balance point moves beyond the front edge of the triangle, the forklift tips forward.

The risk increases if the load is elevated or the mast is tilted forward. Higher speed also increases the force involved in stopping.

Maintaining safe travel speeds and adequate stopping distance reduces the likelihood of sudden, aggressive braking that pushes the forklift beyond its stable zone.

Scenario 3: Uneven or Off-Centre Loads

Not every pallet is perfectly balanced.

Product may shift during transport, cartons may be stacked unevenly, or a load may extend further past one fork. Even a damaged pallet can create imbalance.

When weight is uneven, the centre of gravity shifts toward the heavier side. That shift might be small, but it reduces your stability margin. Add turning, braking or surface variation and the risk increases quickly.

The forklift may still be within its rated capacity, but stability is not just about total weight. It is about weight distribution.

Checking load condition, spacing forks correctly and exercising extra caution with irregular loads helps maintain balance within the triangle.

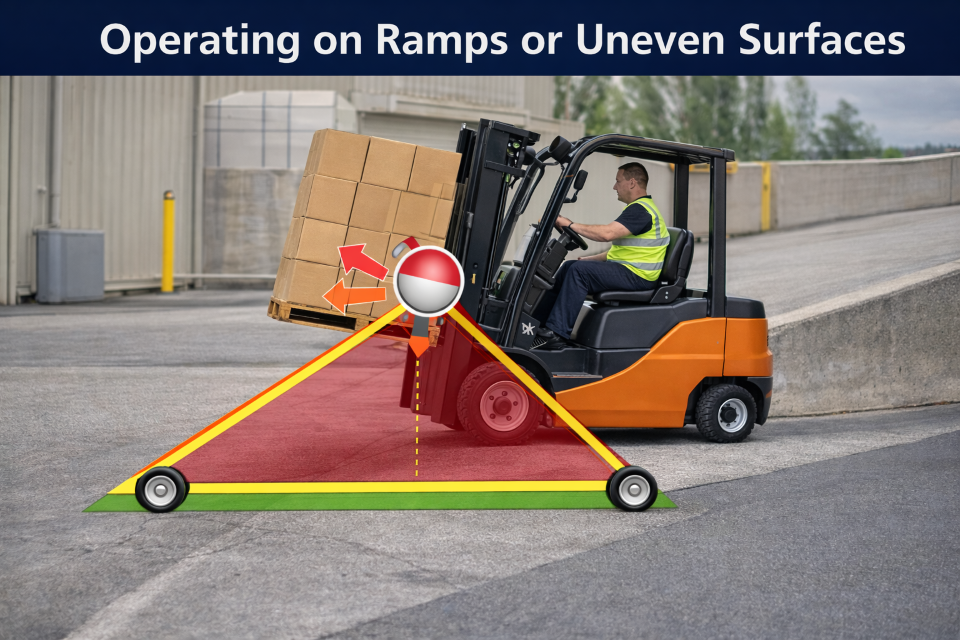

Scenario 4: Ramps and Uneven Surfaces

Loading docks, yard areas and ramps introduce another layer of risk.

On an incline, the centre of gravity shifts depending on travel direction. Driving downhill with a load moves weight forward. If the load is raised or braking occurs at the same time, the risk of a forward tip-over increases.

Side slopes push the centre of gravity toward the lower side of the forklift. Turning on a slope compounds that effect.

Uneven surfaces such as potholes or dock plates can also cause sudden shifts in balance when one wheel drops or rises unexpectedly.

Travelling with the load facing uphill, keeping loads low and avoiding turns on slopes are simple but critical stability practices.

Read more about

how to improve forklift safety and prevent accidents...

How Load Height Changes Everything

Load height has a major impact on stability.

When a load is low, the combined centre of gravity remains lower, increasing stability. As the load is raised, that balance point rises and the forklift becomes more sensitive to movement.

At height, turning forces, braking forces and steering inputs have a greater effect. The margin for error shrinks.

This is why safe operating procedures emphasise travelling with loads lowered and only raising them when stationary and positioned at racking. Height amplifies every other stability factor.

Common Myths About Forklift Stability

There are a few persistent myths about forklift stability that sound logical but do not hold up when you look at how the stability triangle actually works. These misconceptions often lead to overconfidence, which is where risk starts to build.

“If it’s rated for 2.5 tonnes, it can lift 2.5 tonnes anywhere.”

Not necessarily. Capacity ratings are based on specific load centres and conditions. Raise the load, extend it forward, or add an attachment and the effective capacity changes. The stability triangle does not care about the number on the badge. It only responds to where the combined centre of gravity sits.

“Speed is the only thing that causes tip-overs.”

Speed plays a role, but it is not the whole story. Turning too quickly, braking hard, or lifting a load too high can all push the centre of gravity outside the triangle, even at moderate speeds. Stability is about balance and force, not just how fast the forklift is moving.

“A bigger forklift is automatically safer.”

A heavier machine may have a wider stability base, but that does not make it immune to physics. An oversized forklift carrying an uneven or elevated load can still tip if the centre of gravity moves beyond the triangle. Size increases margin, but it does not eliminate risk.

“If the load feels stable, it is stable.”

Forklifts can feel stable right up until the tipping point. There is often very little warning. The stability triangle works on exact balance. Once the centre of gravity crosses that boundary, recovery is unlikely.

How Operators Can Stay Within the Stability Triangle

Stability comes down to smooth, controlled operation.

- Keep loads low while travelling.

- Slow down before turning.

- Avoid sudden braking.

- Check load balance before lifting.

- Understand the forklift’s capacity plate.

- Adjust driving style for ramps, uneven surfaces and tight spaces.

Good operators are constantly aware of where the

centre of gravity sits and how their actions influence it.

Conclusion

The forklift stability triangle is not just a training diagram. It explains nearly every tip-over scenario in a warehouse.

Whether it involves turning, braking, uneven loads or slopes, the outcome is the same: the centre of gravity moves. If it crosses the boundary of the triangle, the forklift tips.

When operators understand how stability works in real conditions, they can adjust before instability occurs.

Forklift safety is not about luck. It is about understanding physics and applying it every time the machine moves.